|

|

|

We

have designed and/or built many custom tools for underwater applications.

Most of our applications have been in reactor internal modifications and

fuel pool work. For decommissioning work we have modified some of our

repair tools for destructive work. We

have designed and/or built many custom tools for underwater applications.

Most of our applications have been in reactor internal modifications and

fuel pool work. For decommissioning work we have modified some of our

repair tools for destructive work.

We can supply tools that utilize the following

processes:

| • |

Milling for Core

Barrel modification, Thermal Shield removal and repair, and many Reactor

Internals Modification projects. |

| • |

Electrical Discharge

Machining (EDM) for retrieving metal samples, fuel pin repair, component

modification, and general chip-less machining. |

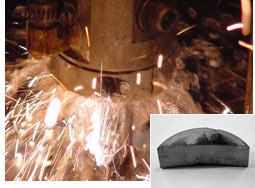

| • |

Metal Disintegration

Machining (MDM) for fuel pool re-racks, destructive cutting, bolt

removal, stuck studs, thermal shield removal, split-pin removal, decommissioning

work, and general chip-less machining. |

| • |

Plasma Arc Cutting

(PAC) for modifications of large stainless components and decommissioning

work. |

| • |

Abrasive Water

Jet (AWJ) for component removal and decommissioning. This process

has some underwater limitations but can be used effectively in the

correct applications. |

| • |

Camera systems

used for weld inspection, monitoring a process, overview of a machine,

pipe inspection, crack location and sizing, internals inspction, vessel

head inspction and repair, and many other applications. We have a

teaming partner that is a manufacturer of Remote Operated Vehicles

(ROV) that can be used in fuel pools for inspection and other uses.

|

|

|